3 Important Benefits of Component-Based Construction in Commercial Lounge Seating

Facilities personnel have always needed cost-effective, yet high performing products for their buildings. That need is even greater today. With Covid-19 impacting every facility, budgets are tight and maintaining facilities can be costly.

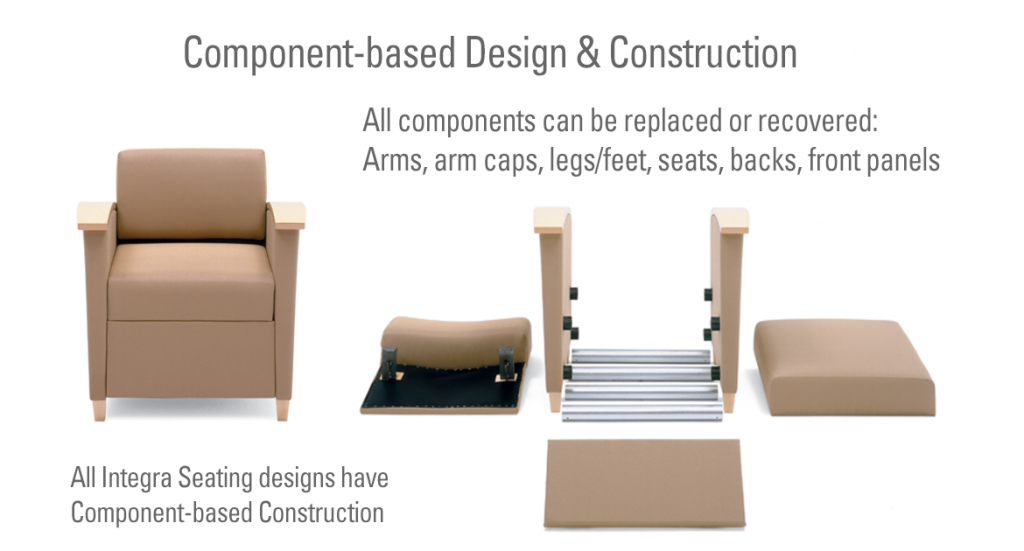

One way facility managers can save money and protect their investment is to select furniture with replaceable and/or recoverable components. While not a new concept, many lounge seating and table products on the market do not have this extremely important attribute. This is a design philosophy Integra has incorporated into every seating series since its beginning more than 38 years ago.

As a commercial lounge seating manufacturer, we know the intense use these products go through. Whether it’s in a hospital, university, workplace, or any public area, lounge seating is utilized by people of varying body types and in multiple ways. Often times, the products are in use 24 hours a day, 7 days a week. We recognized early that this constant use (and sometimes abuse) requires not only a highly durable product, but one in which Integra seating parts can easily be recovered or replaced. This will significantly reduce the facility’s expense related to any product damage and fabric failures.

Definitions: Replaceable and Recoverable

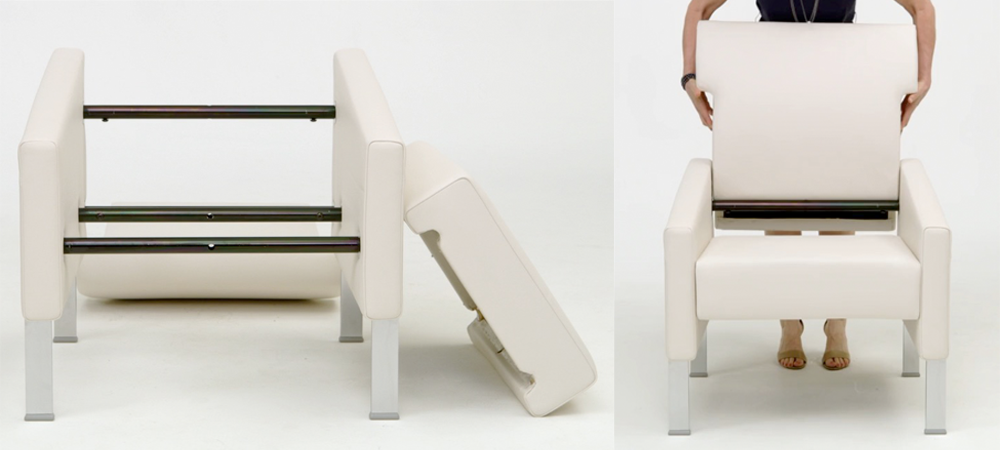

At Integra, we refer to “replaceable” as it relates to the various components of the furniture. Every single seating line (yes, every one!) and most of the tables we make come with replaceable parts. These include legs, feet, arms, arm caps, seats and backs. From Day One, we intentionally designed our seating with a modular format.

When talking about “recoverable,” we’re referring to the fabric and any item that is upholstered. This can be the seat covers, the back covers, the arms covers, etc. We use a stapled upholstery process which provides the best, most tailored look time after time even after the units have been re-upholstered.

When talking about “recoverable,” we’re referring to the fabric and any item that is upholstered. This can be the seat covers, the back covers, the arms covers, etc. We use a stapled upholstery process which provides the best, most tailored look time after time even after the units have been re-upholstered.

Benefits to Components-based Furniture

By selecting seating with replaceable or recoverable components, facilities gain three essential benefits (not necessarily in order of importance):

Benefit #1. Lowers Total Cost of Ownership

When we buy furniture, we need it to look good for the longest period possible. In commercial and public spaces, the high use can result in damage. Buying a product that can be easily repaired or replaced is both a financial and environmental benefit. It’s much more cost effective and sustainable to repair or replace a furniture component than buying a furniture product whose parts cannot purposefully be taken apart to be repaired or replaced.

Facilities personnel need to control costs. One way to responsibly determine the cost of a product is often referred to as the Total Cost of Ownership (TCO). The TCO includes (but is not limited to) repairs, time out of service, or upgrades. If you’re interested, a nice example of how to calculate TCO is provided by manufacturing giant Graco.

A high-quality and proven seating solution with components-based furniture design helps facilities minimize repair and replacement costs, thus lowering the TCO and generating a better Return on Investment (ROI). The greater ROI is derived in two main ways.

One: Replacing/recovering a component is far less expensive than replacing an entire seating product when only one part is damaged. It can be tempting to select a lower-cost product to keep initial cost down. But that lower-cost product, if it needs to be completely replaced, may end up being 2x to 3x more costly than a high-quality and functionally designed product. Also, with replaceable and recoverable parts, there is no need to be environmentally irresponsible and fill our landfills with products that didn’t have these valuable and sensible features designed into them.

Two: If a seating product is not designed with replaceable components, then trying to have a part repaired correctly may be costly. Repair or replacement of an arm, leg, seat, or back would most likely need to be custom work performed by a professional furniture refinisher or repair person, which could be costly and take an extensive amount of time. In addition, not all geographic areas have a person or company with that expertise nearby.

Benefit #2. Minimizes Time Out of Service

Commercial seating products that have any issues in use not only cost money, but also valuable time. After identifying the issues, facilities personnel need the quickest and easiest process for finding a solution.

A component-based seating product with parts that can be more easily replaced saves valuable time. For example, if an Integra arm cap is damaged, it can be quickly and easily replaced by facilities personnel already on site. No additional assistance is needed and the product doesn’t have to be transported to a repair center.

Some manufacturers’ arm caps are glued on and not intended for removal or replacement. In general, damaged arm caps may require a costly repair solution and can be time consuming. Or, in a worst-case scenario, the entire seating product itself may have to be replaced. It can also result in an extensive amount of waste, by discarding the unit and purchasing an entirely new seating product.

Benefit #3. Contributes to Sustainability

Sustainability remains an important consideration in the specification process. There are multiple dimensions that contribute to sustainability, so taking a multi-faceted approach is critical. Most of our products are Certified Clean-Air Gold and Healthier Hospitals Compliant (Practice Greenhealth and Health Care Without Harm – Healthy Interiors criteria). But, even with those wonderful goals met, we feel that the overall durability is an extremely important factor in the whole sustainability story and complete life cycle assessment.

Not all furniture is created equally. The Business and Institutional Furniture Manufacturers Association (BIFMA) provides a list of safety, durability and performance standards. Visit their site to learn more about the various standards and which manufacturers agree to making all their products to these standards. All Integra’s products meet and exceed these standards in the lounge seating and tables categories.

When it comes to commercial lounge seating and tables, we believe that it should last at least 20 years in service. That is an essential element to the highest sustainability rating. The fabric will most likely need to be replaced at least once in that amount of time, but being able to recover just one component adds to the sustainability.

A fabric that fails or has issues prematurely is another costly issue.

Case in point: There are many textiles that offer sustainable benefits, such as a PVC-free material. However, it’s important to know whether that “sustainable” fabric will last for an extended amount of time or whether it will need to be replaced sooner than expected.

If the fabric fails and needs to be replaced sooner than expected, this has a negative impact far outweighing any sustainability attributes for which it was chosen. And this issue is even greater when the affected parts can’t easily be recovered, therefore having to replace the entire chair. The raw materials, energy and transportation needed to replace the entire unit has negative financial and environmental impacts.

Experts in the healthcare industry have come together to discuss and research textile issues to try to be a catalyst in helping to find a solution to this problem. They are advocating that furniture manufacturers do what Integra has been doing for nearly four decades: develop products with “component-based construction.”

The Center for Health Design hosted a webinar titled, New Information About Specifying and Cleaning Durable Coated Fabrics. During the presentation, one of the panelists, Teri Lura Bennett, RN, CHID, CID, IIDA, EDAC, Lead Interior Design Planner at Johns Hopkins Health System, said this: “Component-based helps, because that way you don’t have throw the whole chair away if the cushion goes bad.”

This was reinforced by another panelist, Linda Gabel, CHID, IIDA and Senior Interior Design Planner at The Ohio State University Wexner Medical Center, who noted that an important factor in healthcare specifications is to “Consider component-based furniture over unitized to easily replace items that are forecasted to degrade over time.” Also noted was how it is necessary to look at the entire lifecycle of the product.

Next Steps:

Designers and facility personnel should be sure to ask whether the seating products they’re considering are component-based. Leaders should also make it a priority to seek out commercial lounge seating manufacturers that hold functional design as a core value in their engineering and manufacturing process.

If you’re interested in reviewing Integra’s seating, all of which come with replaceable or recoverable components, please visit our website at www.integraseating.com.

If you have any questions about how our product solutions can best serve your facility or design need, feel free to contact us directly at 800-235-0234.

Additional Resources

In addition to the sites and resources listed in the article, some others you may want to check out include:

Durable Coated Fabrics Task Group – https://www.durablecoatedfabrics.com

Health Care Without Harm – https://noharm-uscanada.org/

Health Care Without Harm, featuring Integra – https://noharm-uscanada.org/documents/integra

Practice Greenhealth – https://practicegreenhealth.org/healthierhospitals

US Green Building Council – https://www.usgbc.org

Be sure to follow us on social media, where we share design tips, insight into our seating design, and photos from project installations across the U.S.